Choose from a range of refrigeration systems according to your temperature needs and facility size.

The freezing and refrigeration technologies that Mayekawa has developed through a long history of designing, constructing, and servicing refrigeration plants support the reliability and trustworthiness the company’s products have earned.

Additionally, in order to contribute to the prevention of global warming and ozone layer protection, we are increasing our product lineup by continually developing extremely safe and efficient refrigeration systems that use natural refrigerants.

PascalAir - air cycle system

PascalAir

PascalAirSince air acts as the refrigerant, not an HFC, there is no refrigerant-induced impact on the global environment.

Furthermore, in the ultra-low temperature range from -58 to -148℉ (-50 to -100℃), it is possible to reduce CO2 emissions and achieve energy savings of up to 50 percent compared to conventional vapor pressure refrigeration systems.

SPECIFICATIONS

- Cooling capacity: PAS15-R 15kW (4.3TR), room temperature -76℉ (-60℃)

PAS30-R 8.5TR (30kW), room temperature -76℉ (-60℃) - Room temperature: -58 to -148℉ (-50 to -100℃)

- Refrigerant: N.A. (working fluid: air)

WHERE TO USE

- Cold storage for tuna/oceanic bonito

- Rapid freezing

- Freeze-drying

- Home appliance recycling (cryogenic grinding)

- Semiconductor manufacturing processes

- Markets requiring ultra-low temperatures such as the medical, pharmaceutical, and physics/chemistry fields

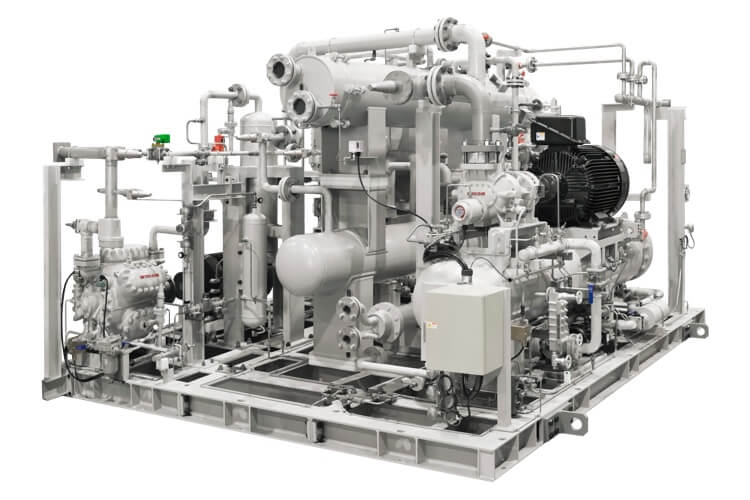

NH3/CO2 cascade refrigeration system

NH3/CO2 cascade refrigeration system

NH3/CO2 cascade refrigeration systemAn environmentally friendly cascade refrigeration system that uses ammonia as a refrigerant on the higher-temperature side and CO2 on the lower-temperature side.

As only CO2 is supplied as the secondary refrigerant, the risks associated with ammonia are minimized. This product is suited for use in situations where low temperatures are needed, such as freezers that have internal temperatures of -40℉ (-40℃) or lower.

By controlling the number of refrigeration compressors on the high-and low-temperature sides, it is possible to operate the system in line with the required load.

SPECIFICATIONS

- Cooling capacity: 42.6 to 227.4TR (150 to 800kW) -40℉ (-40℃)

- Room temperature: -40 to -58℉ (-40 to -50℃)

- Refrigerant: HT side ammonia (R717), LT side CO2 (R744)

WHERE TO USE

- Ice cream hardening line

- Product processing (freezing, freezer, freeze-drying)

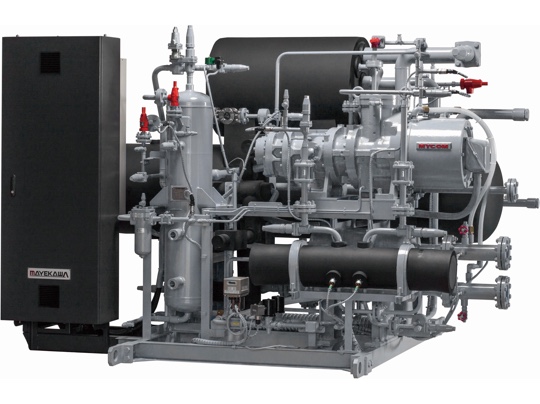

NewTon R/C/F/S - NH3/CO2 cooling system

NewTonC

NewTonC NewTonR

NewTonRDeveloped to counter the global warming impacts of the industrial refrigeration field, NewTon is a highly efficient non-freon refrigeration system that uses natural refrigerants.

Refrigeration compressor manufacturer Mayekawa employs the latest technologies in all of its compressor with IPM(Interior permanent magnet) motor, heat exchangers, and controllers.

Highly energy efficient, NewTon reduces the power consumption of the entire system, thus contributing to the reduction of energy-derived CO2.

Additionally, there is a rich lineup of NewTon products that have been designed to always operate efficiently in line with customer needs from freezer warehouses, cold storages, loading rooms, freezers, vacuum freezing, soil freezing, skating rinks and ice making.

SPECIFICATIONS

- Cooling capacity*:

NewTon C 77.6TR (237.0kW)

NewTon R 26.9 to 76.8TR (94.7 to 270.0kW)

NewTon F 19.9 to 48.3TR (70 to 170kW)

NewTon S 52.6TR (185kW)

*In the case of cooling water at 90℉ (32 ℃) - Room temperature:

NewTon C 36 to 14℉ (2 to -10℃)

NewTon R -4 to -22℉ (-20 to -30℃)

NewTon F -22 to -40℉ (-30 to -40℃)

NewTon S (ice rink) 27 to 23℉ (-3 to -5℃) - Refrigerant: primary ammonia (R717), secondary CO2 (R744)

- Remote monitoring service

WHERE TO USE

- Cold storage

- Ice making plant

- Frozen, chilled food

- Ice arena

Condensing unit

With a core utilizing the MYCOM compressor, which is produced in-house and boasts a wide-ranging lineup, a diverse range of condensing units can be designed and manufactured.

The control panel is also produced in-house.

We will propose the condensing unit most suited to client needs.

SPECIFICATIONS

- Cooling capacity:

30 to 3000 kW (8.5 to 852.9TR) *NH3, Te=-10℃ (14℉)

30 to 8500 kW (8.5 to 2416.6TR) *NH3, Te=-40℃ (-40℉) - Room temperature: -60 to 5℃ (-76 to 41℉)

- Refrigerant: ammonia (R717), HFCs

WHERE TO USE

- Cold storage

- Processed food production processes

- Industrial product processes

- Ice-making plants, etc.