Bread

Better for you, your customers

and the environment

Improved productivity

Frozen dough makes production planning and adjustments easier

Food safety and security

Hygienic production lines

Energy saving

Energy-saving across the entire plant through total engineering

The two benefits of making bread from frozen dough

There are two benefits associated with the making bread from frozen dough where the dough has been portioned, formed, and frozen at a factory is then thawed, fermented, baked, and sold at a store.

One is that as the dough can be frozen and stored at the factory, it makes it easier to draft production plans in line with order forecasts, which in turn reduces operating costs and improves working conditions for employees. The other is that consumers across a wide region can enjoy freshly baked bread through the distribution of dough that has been portioned, formed and had its quality controlled at a factory.

With freezing technology such as highly efficient refrigeration system and high capacity quick-freezing freezers that make bread making from frozen dough possible, Mayekawa assists bakeries in delivering consistently high-quality baked products to consumers.

Stable supply of safe food with a complete and hygienic system

The bread production line is almost entirely automated.With its extensive engineering experience, Mayekawa ensures that the freezers and conveyors incorporated into the line have a simple structure that emphasizes washing and cleanability in the design concept. Our easy-to-wash and hygienic systems contribute to food safety.

Additionally, the overall design, including hygienic aspects such as air shutters that are highly effective at preventing insects from entering facilities through entrances/exits, assists in creating an end-to-end environment where products can be safely and hygienically produced.

Energy-saving for the entire plant with highly efficient equipment and process design

Mayekawa’s engineering improves productivity and reduces power consumption by tracking load fluctuations when switching production lines and quantities, and shortening times needed for freezing with freezers.

Additionally, with freezers specially designed for food factories and air curtains that prevent outside air from coming in reduce air ingress, energy savings can be realized across the entire factory.

In addition we apply our thermal engineering technology to ensure heat and energy used in your factory is done so without waste, by using a heat pump to take waste heat generated from production lines to create hot water for use in the cleaning process.

Become a partner that maximizes your business

The know-how cultivated in domestic and overseas delivery results is organized in Japan, and we collaborate with local corporations and various partner companies around the world, mainly in Japan, to propose production equipment that suits your purpose.

Working to ensure food is delicious

Mayekawa’s main Moriya Plant has a food testing laboratory, CO_Lab., which annually tests more than 160 different foods. Supporting various kinds of testing, such as that related to freezing, thawing, line operation, and detection, the versatile lab plays a role in helping clients manufacture even better products.

Food testing laboratory Co_Lab.

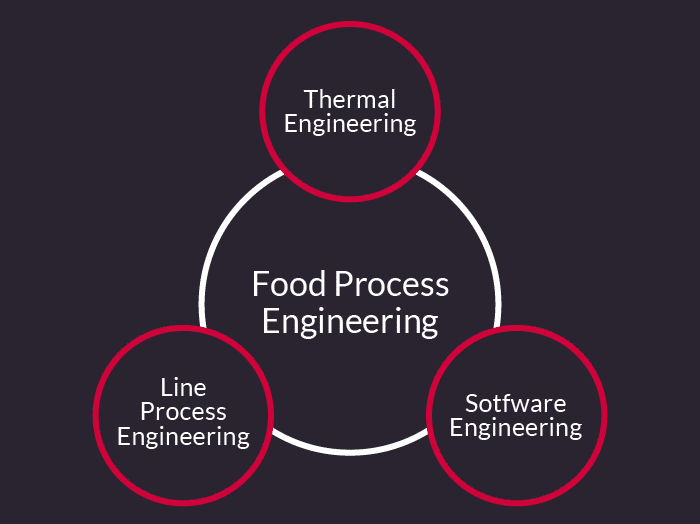

Applying total engineering to solve client problems

In addition to engineering for each process, by also combining thermal engineering centered around advanced equipment and software engineering, including that for production management systems and traceability, Mayekawa can offer optimal solutions for your production line needs.

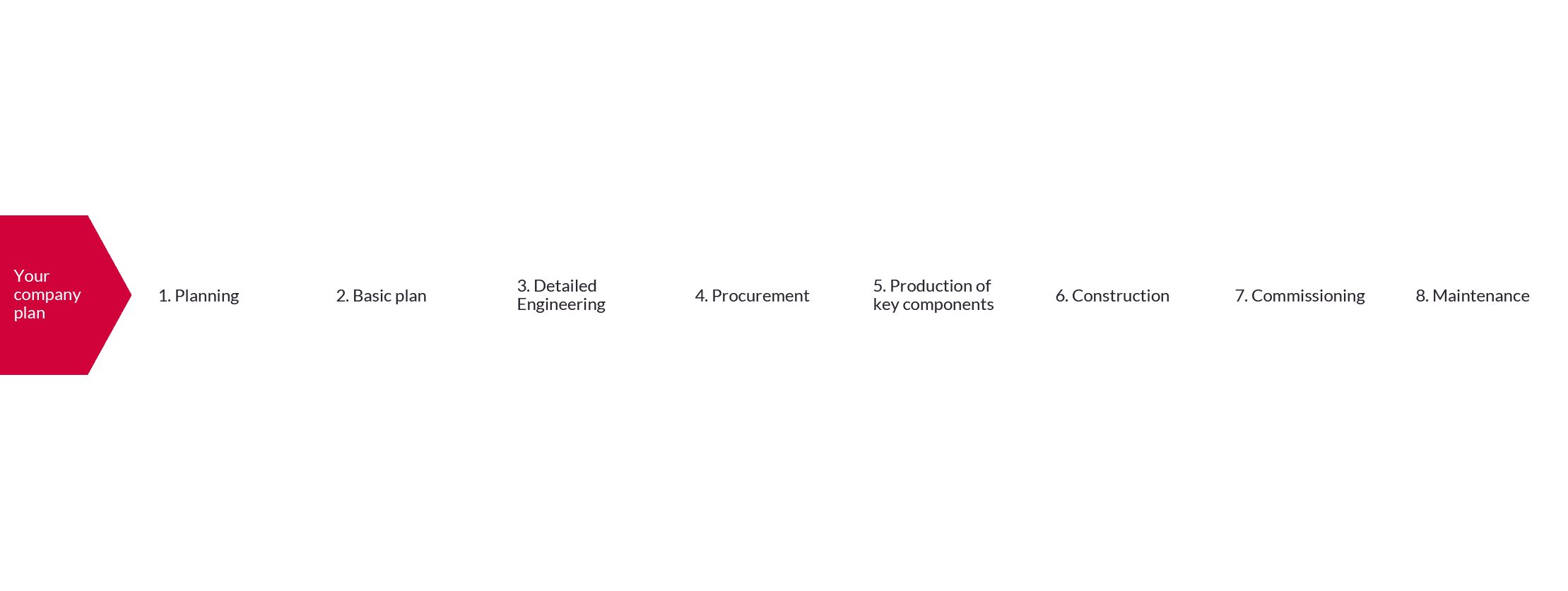

From basic design through to ongoing maintenance, we provide full support for your equipment installation plans

Our head office department specializing in food organizes information related to customer issues and requests. Even after planning has started, we back local sites with know-how and experience gained in delivering equipment all over the world. From basic design through to ongoing maintenance, we can offer manufacturing equipment and services tailored to client needs in collaboration with local subsidiaries and our partner companies around the world.